Each field does have its specific features. If you want to make full use of the potential of your field, you need an individually tailored irrigation system. Determining this is an art that only true irrigation specialists can master. Just like us at BAUER. We have therefore created a special system for large, irregular surfaces: the CENTERLINER 9000. It combines the advantages of a pivot and a linear system in one machine and can even better use the area, especially when it is a spacious, irregularly shaped field. As with the LINESTAR, a central unit drives the CENTERLINER linearly with the trusses over the field. The Centerliner, however can also switch to pivot mode. A special linear control always keeps the machine on the right track. The water is supplied via hydrants and feed hose or ditch feed.

Depending on the field situation and precipitation rates, the CENTERLINER can irrigate the same area as a LINESTAR, but only requires half the number of towers. Which results in lower acquisition costs. In addition, the CENTERLINER can be pulled over to another field.

High degree of flexibility thanks to the easy-to-use tow option.

| CLX | CLE | CLS | Details |

|---|---|---|---|

| ● | 4 wheel central unit for automatic swiveling oft he drive towers with rigid connections at front and rear | ||

| ● | ● | 4 wheel central unit for automatic swiveling of the drive towers with flexible suction connections for automatic reverse | |

| ● | possibility of rotation of the central unit for L-shaped areas | ||

| ● | double connection – for using 2 drag hoses | ||

| ● | ● | ● | central unit towable design |

| ● | ● | ● | control unit SELECT – Pro |

| ● | ● | ● | SMS control unit – optional |

| ● | ● | ● | Span 168LL lengthes: 42,3 m bis 59,8 m |

| ● | Span 203LL lengthes: 42,3 m bis 54,0 m | ||

| ● | ● | ● | Span – in towable design |

| ● | ● | Span – high design | |

| ● | ● | ● | Max. recomm. system length: 450 m |

| ● | ● | System capacity up to 200 m³ / h | |

| ● | System capacity up to 400 m³ / h | ||

| ● | ● | ● | Drag hose 4″ – max. 200 m (upt to 120 m³/ h) |

| ● | ● | ● | Drag hose4 1/2″ – max. 160 m (up to 50 m³ / h) |

| ● | ● | ● | Drag hose 5″ – max. 130 m (up to 200 m³ /h) |

| ● | Drag hose 6″ – max. 110 m (up to 300 m³ /h) | ||

| ● | ● | ● | Furrow guidanance |

| ● | ● | Cable guidance | |

| ● | ● | ● | Burried guidance |

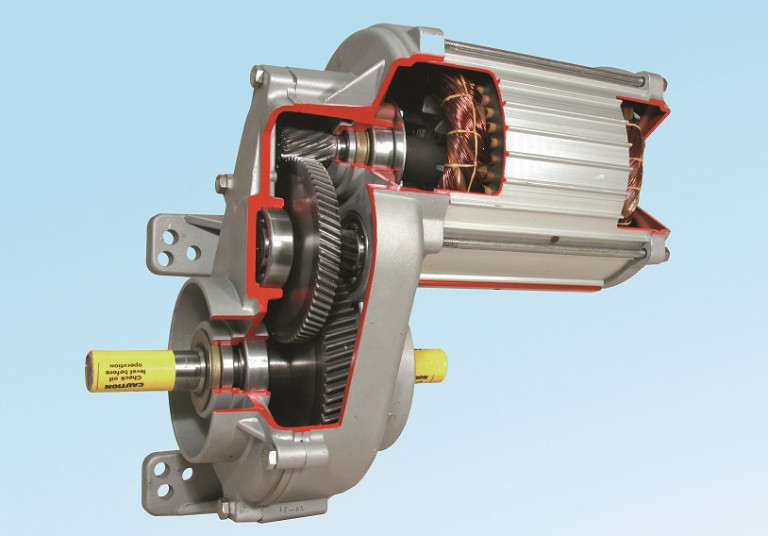

The sturdy drive tower coupling, free from play, with ball and socket perfectly compensates for extreme slopes. Mounted on the outside of the pipe, it does not restrict the cross-section of the mainline pipe, thereby ensuring optimum water flow without pressure loss. The weather, UV and ozone-resistant hose collar facilitates large angles.

BAUER is the only manufacturer to offer a control lever that is mounted directly above the swivel point of the flexible joint. Any torsion in the pipe has no influence on the control; the entire system is kept stress-free. Optimum adjustment of switching brackets with precision bearings of the control cams ensures precise movement transmission. Precise drive tower control system leads to a long product lifespan.

The precision control for all Linestar and Centerliner systems (regardless of the number of spans) and for Centerstar systems with more than 12 drive towers offers utmost accuracy. The angles between the drive towers are transmitted by means of control cables, counter-balancing any torsion in the steel structure.

Tried and trusted sturdy elements for application under the most extreme conditions. Easy-to-use control surface and robust control elements to ensure smooth operation. All of the basic functions for automatic operation are integrated into all of the control centres. A comprehensive range of accessories is available for retrofitting further elements for additional operating functions.

The GPS-supported application SmartRain offers new possibilities in irrigation management. No matter where the user is, he is always informed about the current status of his irrigation system and can also remotely control the machine at any time.

Using GPS modules and an RTK base station, the ACTUAL position is constantly compared with the TARGET position of the machine and corrected immediately if necessary. GPS control is available as an option for Linestars and Centerliners with a 4-wheel central unit and SmartTouch control box.

Advantages of the GPS control:

Sensors track the induction field of a buried cable and thus indicate the moving direction (available for Centerliner and Linestar).

Advantages of the buried guidance wire:

The steering arm with its pulleys moves along a stretched cable, thereby determining the moving direction of the machine.

In order to control a Linestar or Centerliner, a furrow is created along the route in order to determine the moving direction of the system

Find out everything about our new innovative systems for pivot systems from BAUER.