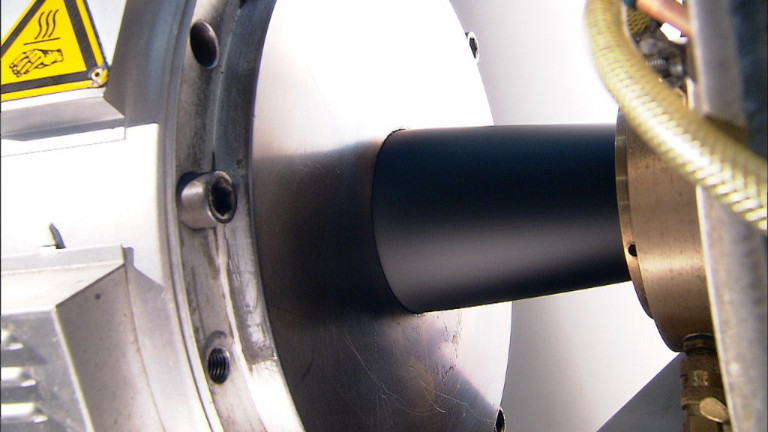

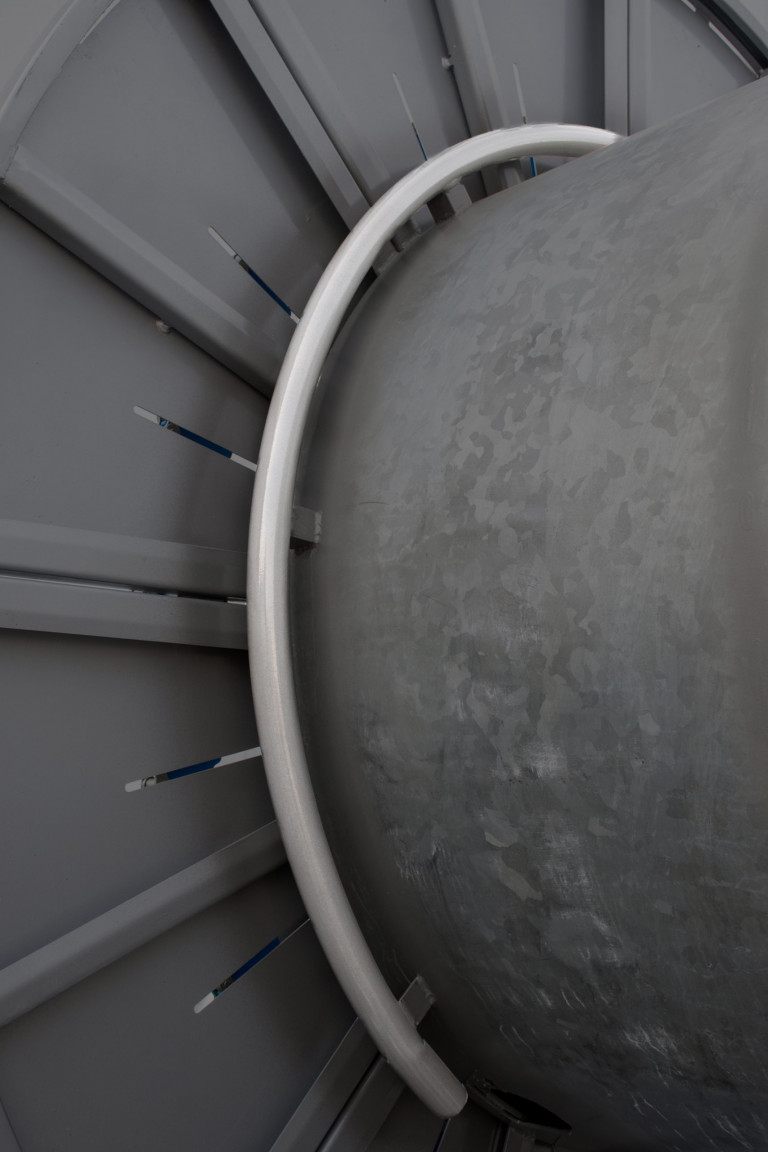

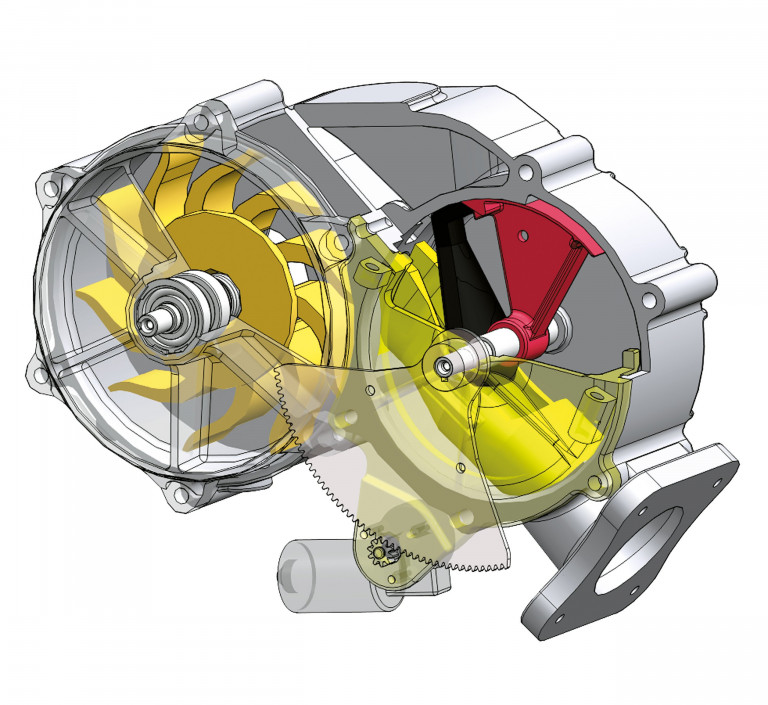

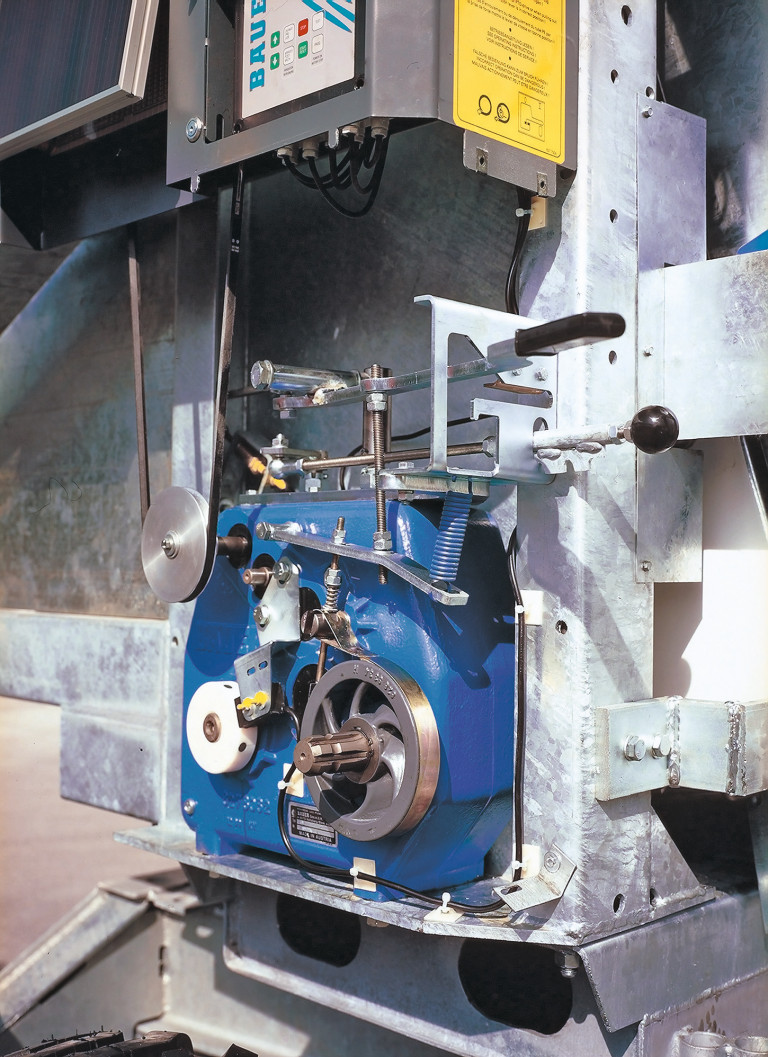

The radial full-flow economy turbine TVR 60 with the unique VARIO NOZZLE is a power pack and energy saver in one. No matter if small or water saving precipitation rates or high amounts of water need to be dealt with - the TVR 60 turbine convinces with a high degree of efficiency and low pressure losses over the whole range of power.

Even under particularly difficult operating conditions, the turbine still has reserves for operational safety, resulting in enormous cost savings and minimum pressure losses in normal operation.

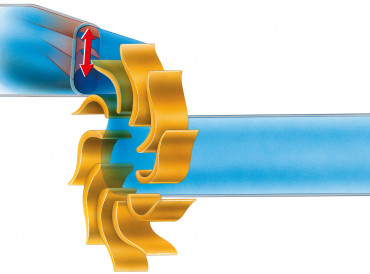

Maximum use of output is achieved by direct flow from the Vario nozzle onto the impeller. At maximum and minimum nozzle settings, the full stream flows over the turbine's impeller. This way a high efficiency can be achieved with every flow rate with a low loss of pressure.