Since the appearance of agricultural structures, people have known about the importance of organic sources of fertilizer. Liquid manure has always been one of the most valuable natural fertilizers. Well-agitated slurry guarantees even nutrient distribution - which means optimal growth and increased yield. Optimum homogenisation of fluid media in agriculture, biogas- and sewage plants but also in the industrial sector.

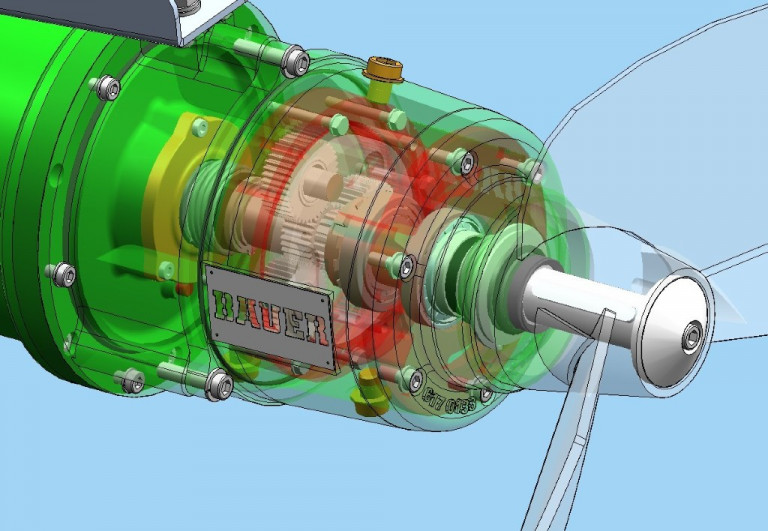

A special concept with the motor and propeller shafts lying on the same axis provides high efficiency. The slim, flow-optimised design resulting thereof further increases efficiency. The propeller shaft is strongly dimensioned and equipped with angular contact roller bearings. The ingenious oil distribution system ensures perfect lubrication of the gearbox at an inclination angle of +/- 30°. Seal probes are standard equipment on the MSXH models.

A central element of the submersible mixer is the planetary gearbox. Several highly hardened and ground toothed wheels are engaged simultaneously which reduces friction and saves electricity. In combination with the large mixer blade and special stirring edges a high degree of efficiency is achieved.

| MSX/MSXH | MSXH 5.5 | MSXH 7.5 | MSX/MSXH 8.6 | MSXH 11 | MSXH 11 ECO | MSX/MSXH 12.6 | MSXH 15 |

|---|---|---|---|---|---|---|---|

| Output kW | 5,5 | 7,5 | 8,6 | 11 | 11 | 12,6 | 15 |

| Voltage V | 400 | 400 | 240/480 | 400 | 400 | 240/480 | 400 |

| Frequency Hz | 50 | 50 | 60 | 50 | 50 | 60 | 50 |

| Mixing power* m³/h | 2.800 | 3.600 | 3.900 | 5.200 | 5.700 | 5.700 | 6.800 |

| Pit volume* m³ | 900 | 1.400 | 1.500 | 2.200 | 2.400 | 2.400 | 2.800 |

| Propeller min-1 | 315 | 315 | 378 | 315 | 208 | 378 | 315 |

| Weight kg | 175 | 195 | 195 | 205 | 205 | 205 | 225 |

Powerful three-phase submersible motor

Thermal protection installed in the motor guarantees total safety in the event of phase failure, overvoltage, undervoltage and overload. Media temperature MSX–40 °C / MSXH–65 °C.

Special shaft sealing

Two high-quality mechanical seals guarantee trouble-free operation and a long service life.

Strong rubber cable

With its secure connection, it guarantees operational reliability even under high tensile loads.

Two-wing thrust propeller with enormous mixing effect

Stainless steel design, self-cleaning, with high efficiency thanks to large diameter and special thrust edge.

Lifting- and lowering device for open and closed containers

Use in deep channel systems

Option: Height-adjustable stirring tunnel with back-up canvas plane ensuring optimum mixing effect.

Slalom system

Automatic homogenisation of the slurry in the ring channel by means of time clock control

Inclinable guide console

Allows to achieve an even better stirring effect and faster dissolution of floating and sinking layers.

Lifting- and lowering device with gas-tight wall interface

Find out everything about our new innovative systems for pivot systems from BAUER.