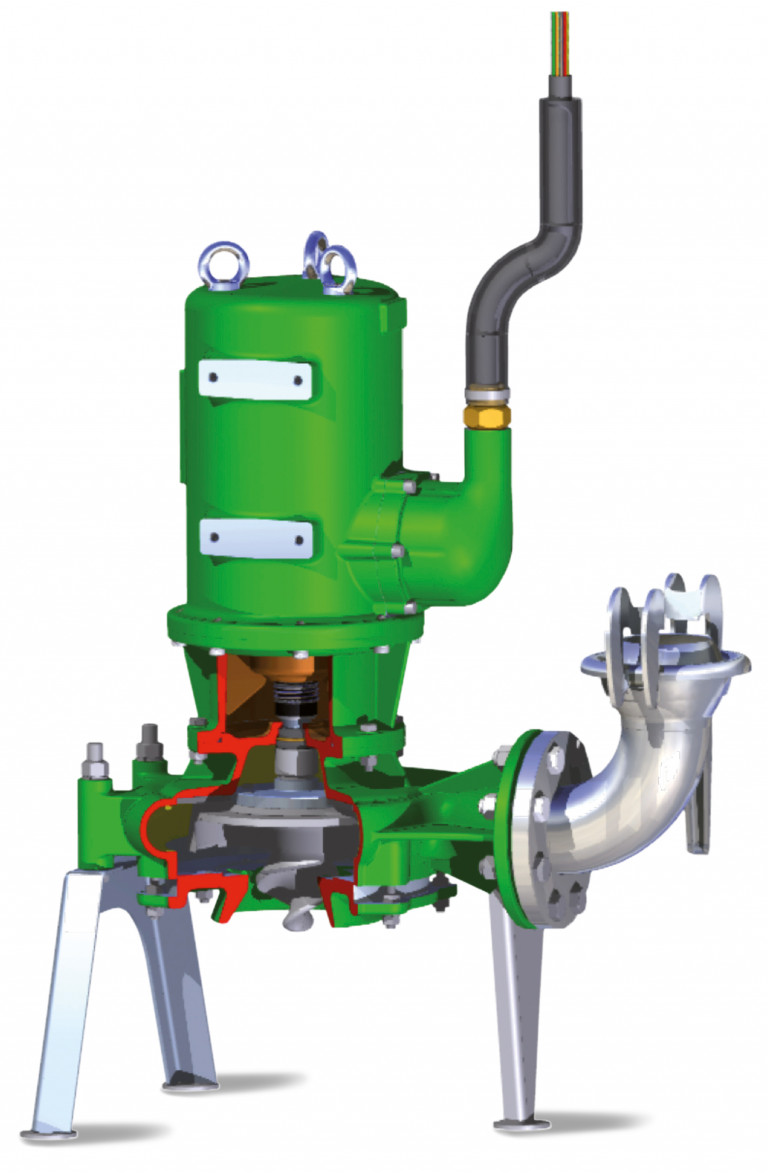

The Bauer submersible pump series ESPH/CSPH impresses with its enormous performance and long service life. The pumps work under the slurry or waste water surface and can be used in a variety of ways.

The main difference between the two versions CSPH and ESPH is the cutting mechanism:

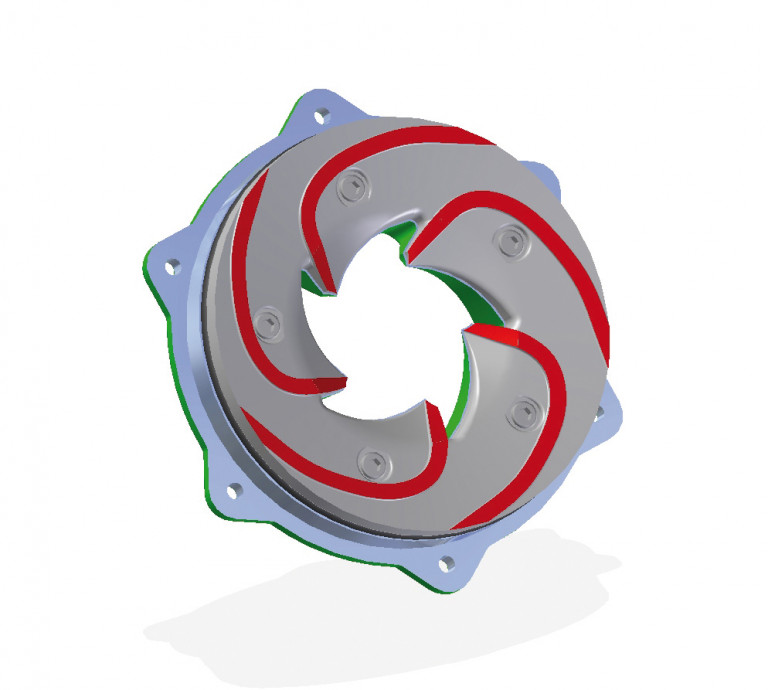

The CSPH (Cutting Submersible Pump) is equipped with an adjustable cutting device. Impeller and cutting disc are made of chrome steel.

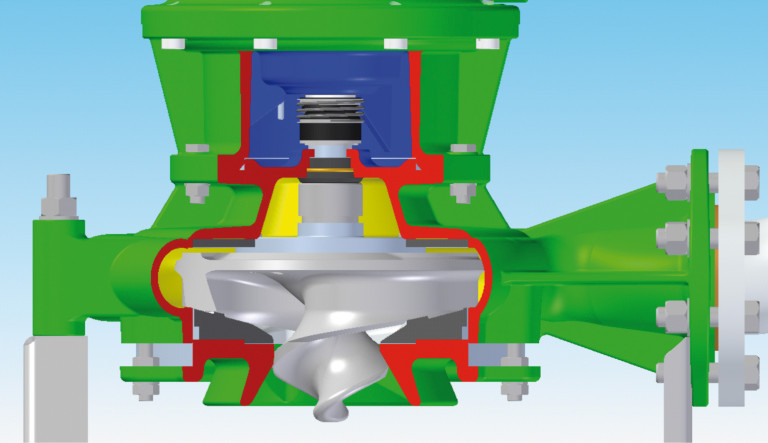

The ESPH (Effluent Submersible Pump) does not have a cutting device. The impeller is made of nodular iron.

The BAUER submersible motor pumps come up with excellent performance data: The CSPH/ESPH can handle up to 80m³ of liquid in one hour at an impeller speed of 1,450 rpm. The pressure height is 13m.

The BAUER submersible motor pumps impress with their performance data: the CSPH/ESPH can handle up to 80m³ of liquid in one hour at an impeller speed of 1,450 rpm. The pressure height is 13m. This makes the pump an excellent match for BAUER Group products such as the BAUER Bedding Unit or the small separator S300.

Of course, the pump is also ideal for use in conventional slurry management applications.

The CSPH/ESPH is ideal for:

One key benefit of CSP/CSPH is the efficient cutting device. The cutter is adjustable and exchangeable and is made of high quality chromium steel which has significantly improved the cutting performance and product lifespan. Also the wear plate in the spiral casing can be exchanged.

Thanks to a special geometry of impeller and suction bell, excellent efficiency can be achieved over a wide range. This clearly distinguishes the Bauer ESPH/CSPH series from other products on the market.

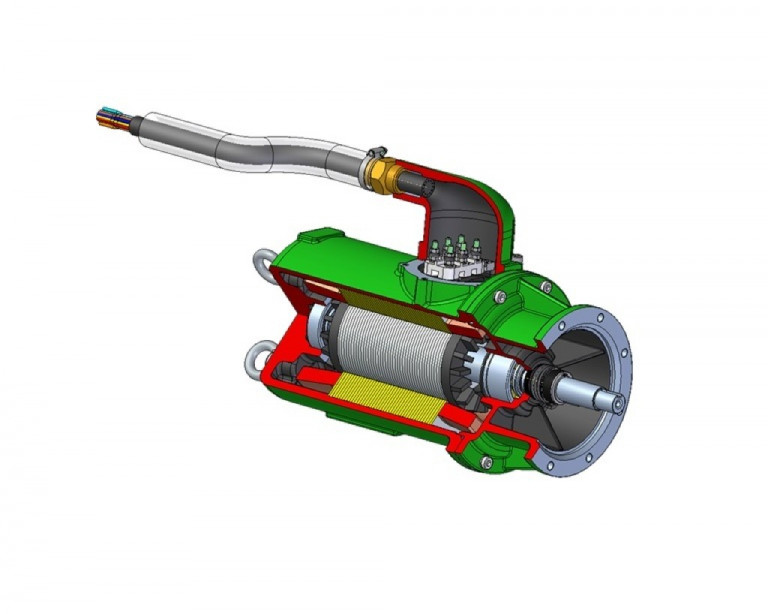

The Magnum submersible pumps are driven by a three-phase submersible motor with 4.0 to 15 kW. The unit has an 88.3% degree of efficiency and therefore corresponds to efficiency category 1. The motor also falls into insulation category H and includes temperature monitoring. This means that the ESPH/CSPH pumps can be used without restriction in biogas plants. A special leakage sensor in the motor adds additional operational safety.

| Model | Discharge m³/h | Discharge head m | max. drive power kW | max. Ampere A | Drive speed min-1 | Delivery connection mm |

|---|---|---|---|---|---|---|

| ESPH 4 | 20-100 | 13,0-7,0 | 4,0 | 8,1 | 1.450 | DN 80 |

| ESPH 5,5 | 20-120 | 20,0-9,8 | 5,5 | 10,7 | 1.450 | DN 80 |

| ESPH 7,5 | 20-200 | 19,6-5,5 | 7,5 | 15,6 | 1.450 | DN 100 |

| ESPH 11 | 20-240 | 22,3-8,2 | 11 | 22,0 | 1.450 | DN 100 |

| ESPH 15 | 20-250 | 24,0-9,1 | 15 | 28,6 | 1.450 | DN 100 |

| Model | Discharge m³/h | Discharge head m | max. drive power kW | max. Ampere A | Drive speed min-1 | Delivery connection mm |

|---|---|---|---|---|---|---|

| CSPH 4 | 20-100 | 12,3-5,9 | 4,0 | 8,1 | 1.450 | DN 80 |

| CSPH 5,5 | 20-120 | 19,2-8,2 | 5,5 | 10,7 | 1.450 | DN 80 |

| CSPH 7,5* | 20-120 | 19,2-8,2 | 7,5 | 14,9 | 1.445 | DN 80 |

| CSPH 7,5 | 20-180 | 19,5-5,1 | 7,5 | 15,6 | 1.450 | DN 100 |

| CSPH 11 | 20-230 | 22,0-6,9 | 11,0 | 22,0 | 1.450 | DN 100 |

| CSPH 15 | 20-240 | 23,7-7,4 | 15,0 | 28,6 | 1.445 | DN 100 |