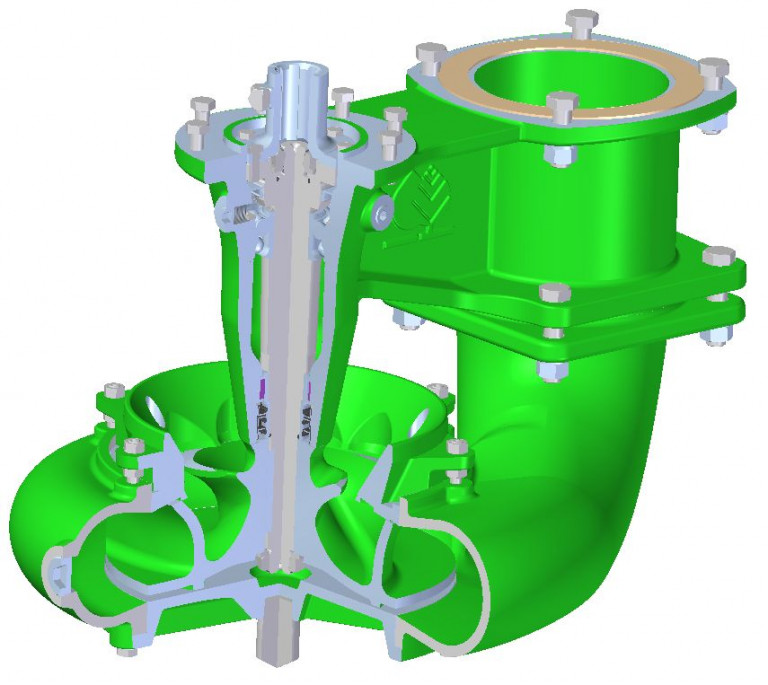

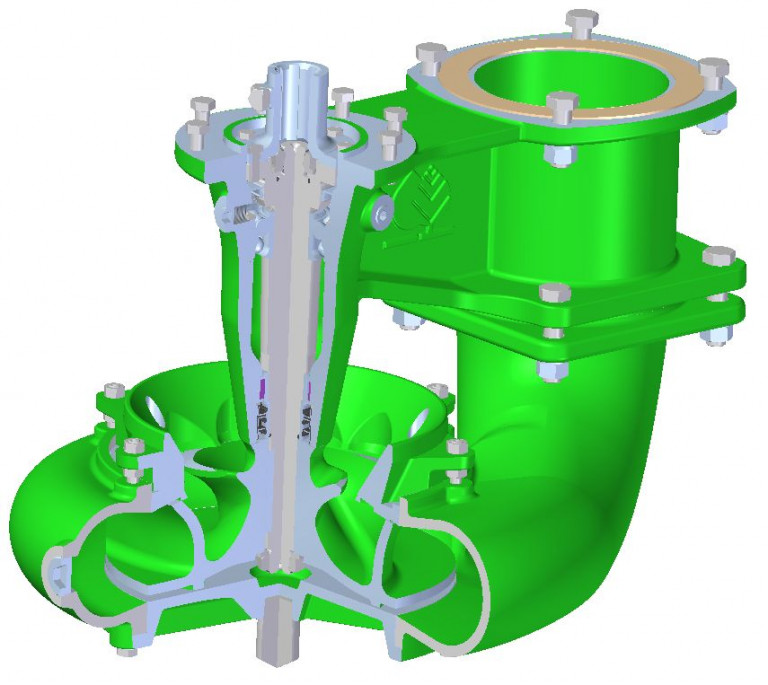

The BAUER long-shaft pumps Magnum LEE and LEC, consisting of pump, drive shaft and electric motor, impress with their excellent energy efficiency and robustness. A distinctive feature is that the actual hydraulic components are always immersed in the medium, the electronic motor, however, is outside the medium. Thus, you never need to worry about damage caused by defective seals.

The two versions, LEE and LEC, mainly differ in the cutting device and are suitable for different liquid manure consistencies:

The LEC (Long Shaft Electrical Cutting Pump) is equipped with an adjustable cutting mechanism and easily handles cattle slurry with a high straw content and feed residues.

The LEE (Long Shaft Electrical Effluent Pump) is built without a cutting mechanism and is suitable for all types of liquid manure with a low straw content and fibrous materials.

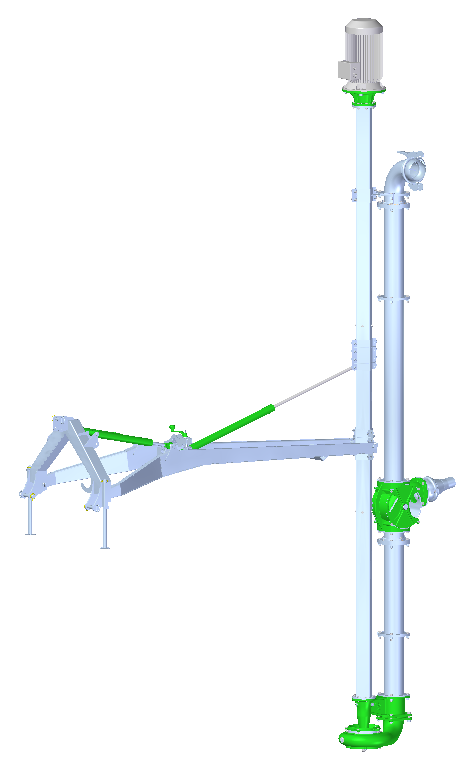

The main advantage of this type of pump is based on the physical fact that the components which are not immersed in the medium do not require sealing and cannot be damaged due to defective seals. In order to benefit from this advantage it is necessary to install a drive shaft between motor and pump, which has different length depending on the depth of the pit. This basic concept and high quality material combined with hydraulically and strength-optimized geometry finally lead to a durable, robust and energy efficient thick matter pump:

The BAUER-long-shaft pump is available in four performance classes in 11 kW; 15 kW; 18,5 kW and 22 kW. Its outstanding characteristics qualify it for the toughest applications:

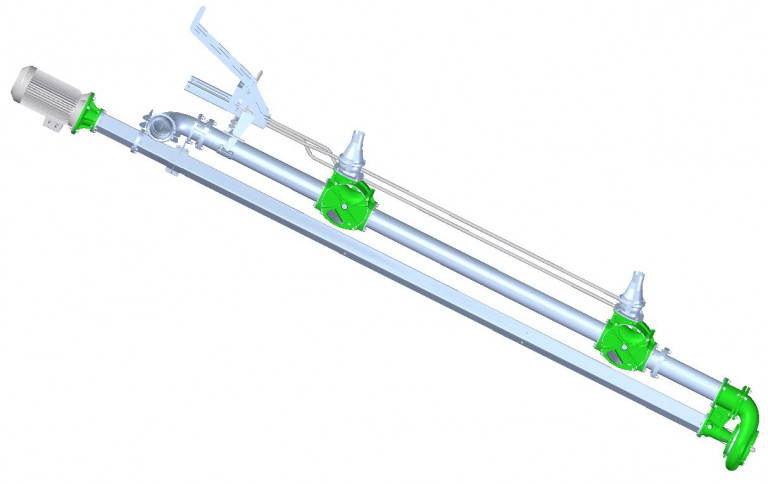

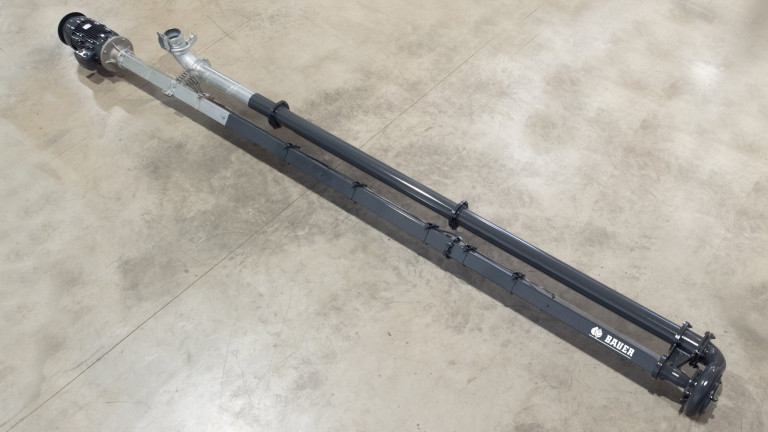

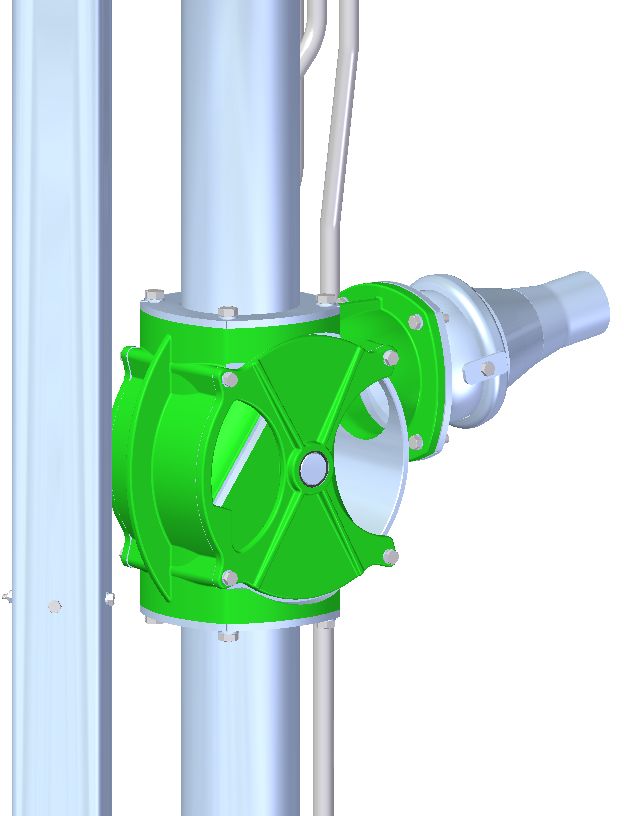

The BAUER long shaft pump LEE/LEC can be placed in the pit for stationary usage with the aid of wall fixtures or fixtures on the edge of the pit. If the pump is used in various pits, the long shaft pump is available assembled on a robust lifting frame.

The LEE/LEC pump is often used for classic applications in the agricultural sector:

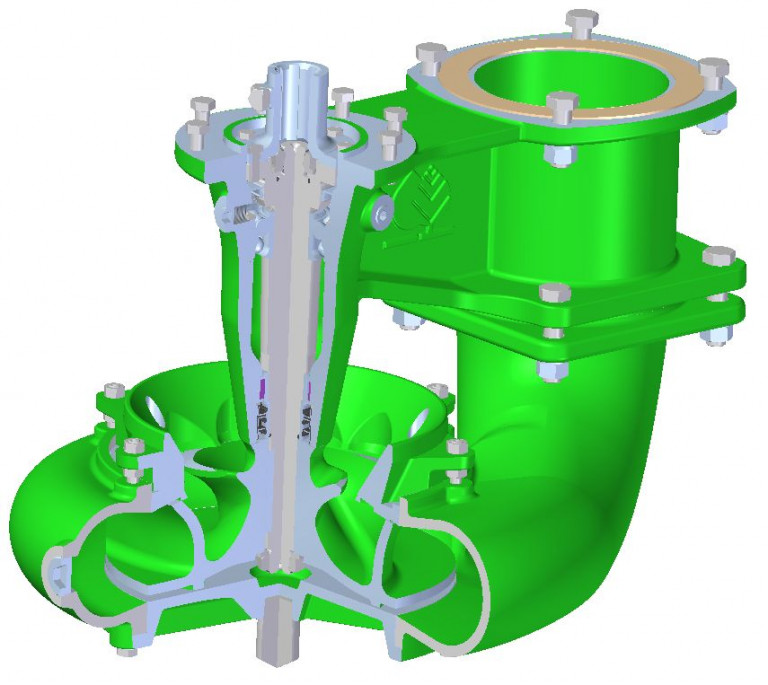

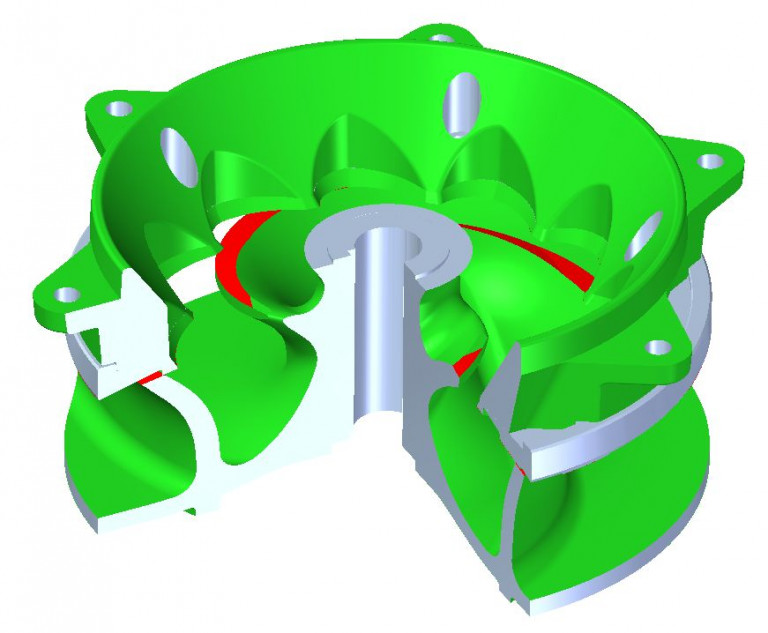

The main component of the long shaft pump is the pump body with the incredibly robust bearing running in oil. The three-part seal provides a high level of safety and prevents oil from escaping and slurry from penetrating the bearing housing.

This gives the BAUER LEE/LEC pump the ideal tools for the toughest operating conditions.

The hydraulic components impeller and spiral housing are arranged directly after the bearing housing. By using modern methods of calculation and simulation programmes as well as hydraulic measurements and optimizations on our pump test bench we were able to develop the ideal hydraulic geometry. The result is convincing: The hydraulic efficiency of the BAUER LEE/LEC long shaft pump is considered to be one of the best on the market.

In order to handle slurry with a high proportion of straw and feed residues you need pumps with an efficient, robust cutting device. No one can and wants to afford downtown times and costs.

By doing intensive thick matter endurance tests under extreme conditions the cutting efficiency has been optimized and the wear resistance increased enormously by using hardened material in order to reach a high lifespan even with highly abrasive mediums. To guarantee this, spheroidal graphite iron is used, which is given special properties through a special heat treatment in order to withstand the toughest operating conditions over a long period of time.

Top feeder means that the pumped liquid does not flow to the impeller from below, as it does with submersible pumps, but from above (on the drive side). The advantage of this design is that heavy objects like screwdrivers, stones or similar objects cannot get into the cutting device and cause damage.

The BAUER-long shaft pump is equipped with a 6 inch pressure pipeline in order to reduce the friction losses in the pipe. An increase of the pressure pipe from 5 inch to 6 inch results in up to 20% savings regarding friction loss with 100 m³/h and 12 % dry matter content in cattle slurry.

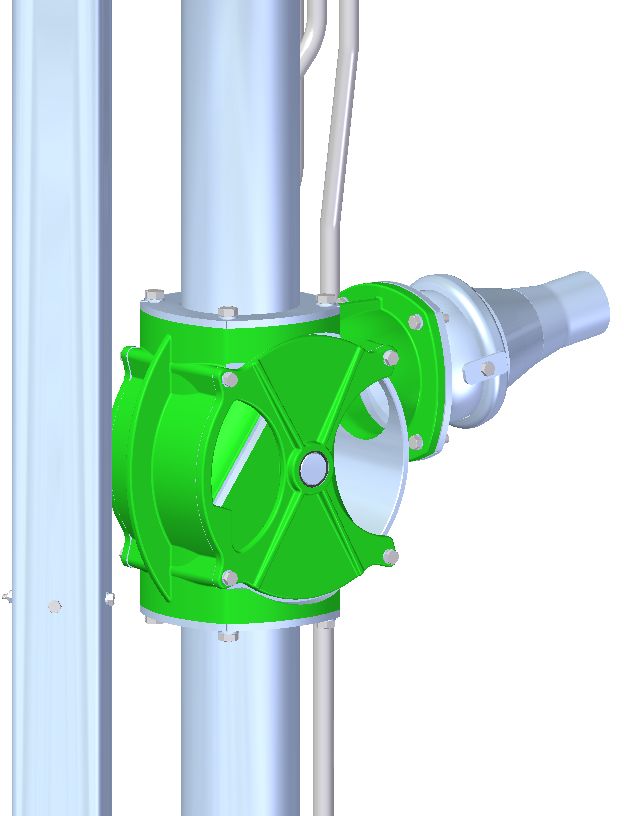

Especially for the use in round and in rectangular pits an agitator nozzle was designed, which has a horizontal swivelling range from up to 180°. Moreover, the nozzle can be swivelled 15° upwards and downwards. This leads to a bigger mixing area and the pit can be mixed thoroughly in a very short time.

With the help of the BAUER-three way valve it is possible to switch easily between mixing and pumping. This way the pump does not have to be switched off and remains in continuous operation when switching between mixing and filling the tanker. By using the BAUER-three way valve the switch-on frequency is being reduced. This has a positive effect on the lifespan of the electric motor and the pump.

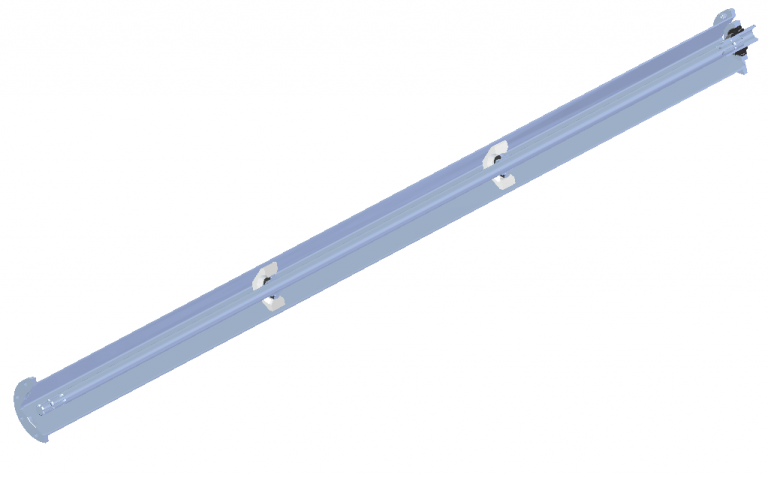

The drive shaft of the BAUER-long-shaft pump was designed for extreme operating conditions and has proven its strength already in use with the BAUER-slurry mixers Turbomix MTXH. This drive train has a drive shaft with specially developed multiple bearings and sits in a massive shaped tube 120x120x4. This leads to an energy efficient and quiet operation. The Bauer-long-shaft pump is available for pits with depth of 2 to 6 meters in 0,5-meter gradations.

| Magnum LEE/LEC | max. operational performance* [kW] | Operating rotations *[min-1] | Extraction flow* [m3/h] | Extraction flow* [l/min] | Extraction height* [m] | |

|---|---|---|---|---|---|---|

| 11,0 | 9,0 - 11,0 | 1.475 | 40 - 300 | 667 - 5.000 | 15,0 - 4,0 | |

| 15,0 | 11,0 - 15,0 | 1.475 | 55 - 350 | 917 - 5.833 | 18,0 - 5,0 | |

| 18,5 | 12,0 - 18,5 | 1.475 | 70 - 370 | 1.167 - 6.167 | 20,0 - 7,0 | |

| 22,0 | 13,0 - 22,0 | 1.475 | 80 - 400 | 1.333 - 6.667 | 22,0 - 7,0 |

| Magnum LEE/LEC | Model Pit depth including. cover (GT) [m] max. fluid level height (FS) [m] | 2,0 2,3 2,0 | 2,5 2,8 2,5 | 3,0 3,3 3,0 | 3,5 3,8 3,5 | 4,0 4,3 4,0 | 4,5 4,8 4,5 | 5,0 5,3 5,0 | 5,5 5,8 5,5 | 6,0 6,3 6,0 |

|---|---|---|---|---|---|---|---|---|---|---|

| Rührdüsenanzahl 0 | Grubendecke - Motorflansch (GM) m ca. | 0,99 | 0,84 | 0,99 | 0,84 | |||||

| Grubendecke - Druckanschluss Bogen (GDB) m ca. | 0,37 | 0,37 | 0,37 | 0,37 | ||||||

| Grubendecke - Druckanschluss gerade (GDG) m ca. | 0,52 | 0,52 | 0,52 | 0,52 | ||||||

| Rührdüsenanzahl 1* | Grubendecke - Motorflansch (GM) m ca. | 0,99 | 0,84 | 0,99 | 0,84 | |||||

| Grubendecke - Druckanschluss Bogen (GDB) m ca. | 0,48 | 0,48 | 0,48 | 0,48 | ||||||

| Grubendecke - Druckanschluss gerade (GDG) m ca. | 0,63 | 0,63 | 0,63 | 0,63 | ||||||

| Rührdüsenanzahl 2** | Grubendecke - Motorflansch (GM) m ca. | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich | |||||

| Grubendecke - Druckanschluss Bogen (GDB) m ca. | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich | ||||||

| Grubendecke - Druckanschluss gerade (GDG) m ca. | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich | Nicht erhältlich |

Find out everything about our new innovative systems for pivot systems from BAUER.