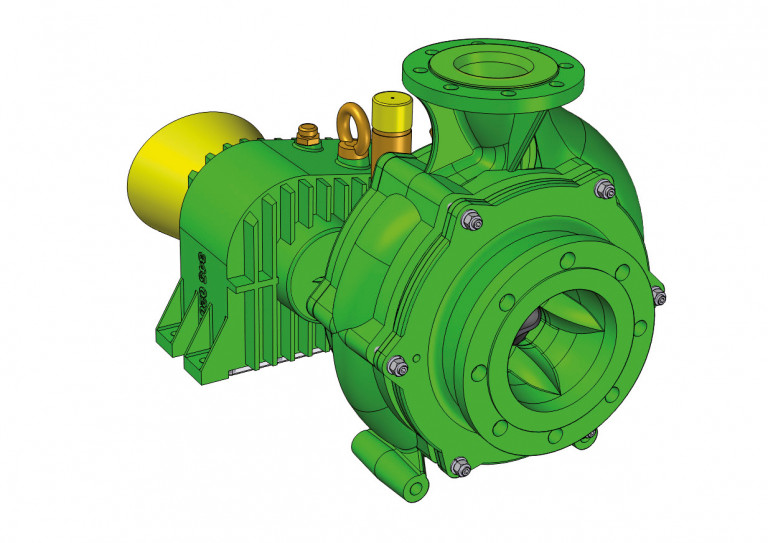

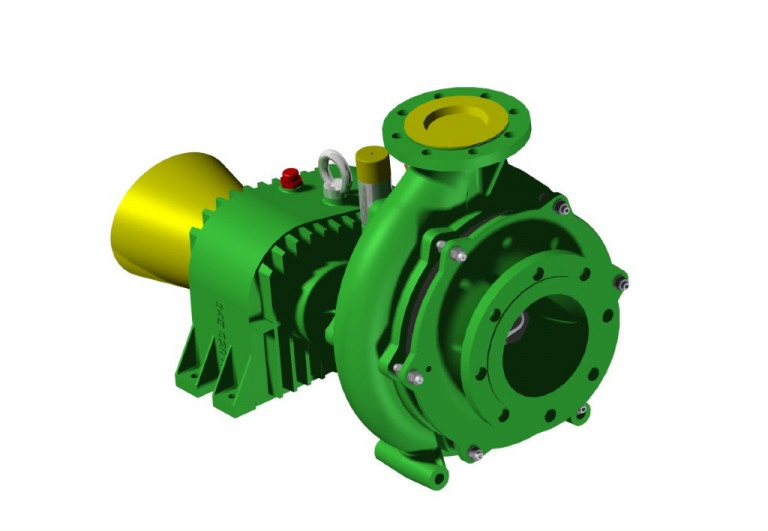

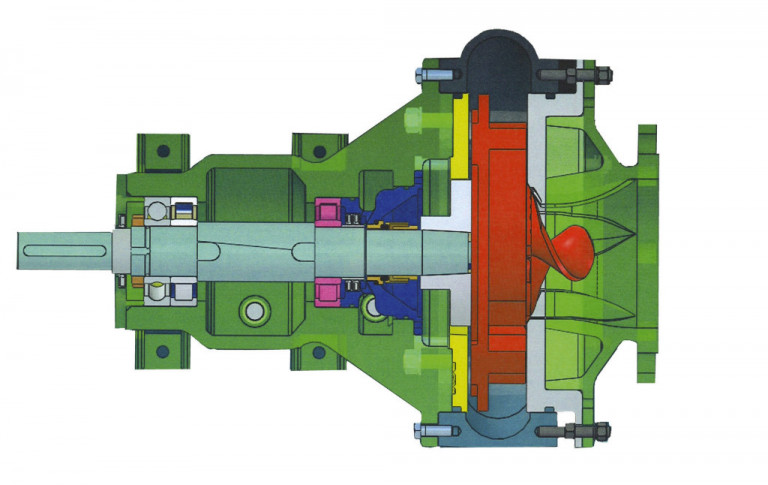

he MAGNUM SX series from BAUER impresses with its excellent shredding effect and considerable pump heights. These gear and pedestal pumps are available in four versions:

The name of the SM 540 may be different, but its features are the same as the SX 1000, with the only difference being that it is smaller.

The BAUER Magnum SX and SM pumps are specially designed for thick matters and pump liquid manure with up to 12% DM. These pumps, however, are also absolutely convincing in many other respects:

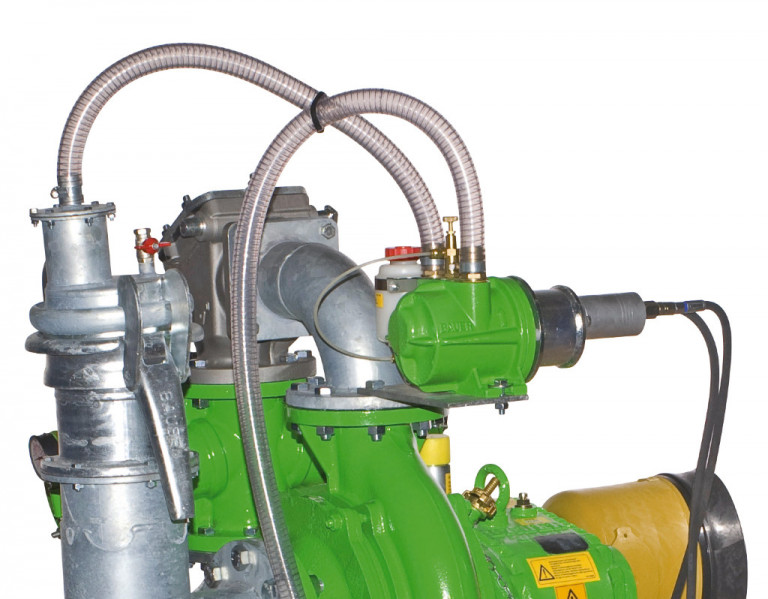

The BAUER Magnum centrifugal pumps are not only used in the agricultural sector. They are also extremely popular for industrial applications.

The MAGNUM centrifugal pump can be mounted in many different ways. This gives it practical flexibility.

| Model | impeller/blades | Flow rate m³/h | flow head m | max. power kW | input speed min-1 |

|---|---|---|---|---|---|

| Magnum SX 1000 | 41 x 348/4 | 60-300 | 140-102 | 130 | 1.000 |

| Magnum SX 2000 | 41 x 348/4 | 60-300 | 140-102 | 130 | 2.000 |

| Magnum SX 2600 | 41 x 348/4 | 60-300 | 140-102 | 130 | 2.600 |

| Model | impeller/ blades | flow rate m³/h | flow head m | max. power kW | input speed min-1 |

|---|---|---|---|---|---|

| Magnum SM 540 L4 | 41 x 263/4 | 40-200 | 95-70 | bis 65 | 540 |

| Magnum SM 540 L4-M | 41 x 230/4 | 40-200 | 72-52 | bis 45 | 540 |

The world’s second largest potato starch manufacturer is located in Jutland. With the popular SX 2600 pumps, production can be carried out reliably and at full speed.

AKM was looking for powerful pumps that could move large volumes over long distances. In addition, they should be suitable for continuous operation and particularly resistant to abrasion and have a high level of operational reliability.

Find out everything about our new innovative systems for pivot systems from BAUER.