What is important to the farmer is a manageable technology, robust over many years and which meets the requirements of the livestock regarding cost-benefit ratio and the correct and proper distribution of liquid manure.

BAUER slurry tankers have been a guarantee of durability and lasting value for decades. Their reliability and models adapted to the geographical conditions of use, give the Bauer slurry tankers their well-known image. A low centre of gravity qualifies the vacuum tankers for mountainous regions and also results in incomparable trailing behaviour.

Bauer Group - the synergy advantage Thanks to its high level of in-house design and production, BAUER offers perfectly matched tanker components. For this reason, the production of components within the Bauer Group offers a high level of technological advancement.

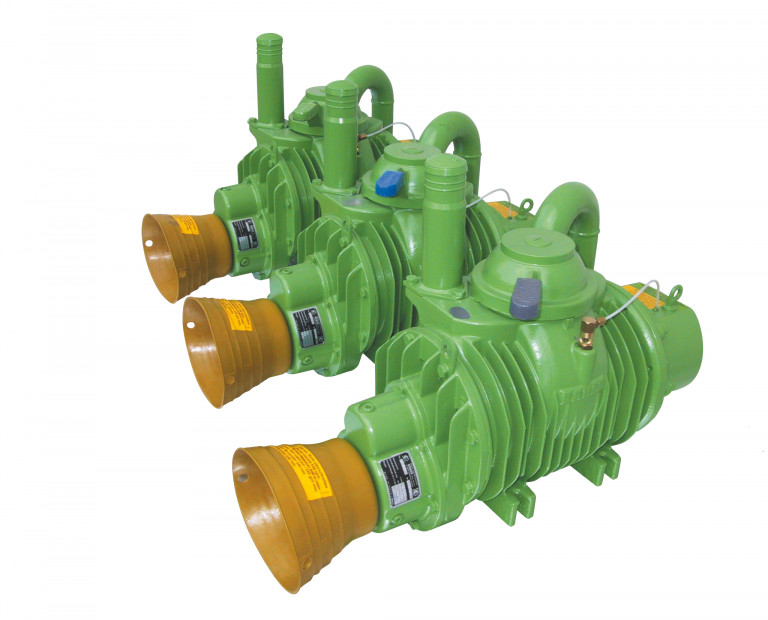

For decades, the BAUER compressor has been synonymous with reliability and durability. High-quality lamellar graphite cast and the very precise machining on CNC-controlled machining centres enable a high degree of efficiency, which is reflected in the world-famous suction and pressure characteristics. Every compressor has to prove its high performance requirements for vacuum and pressure on the factory's own test bench - only then is it delivered to you.

![IMG_E5572[1]](https://www.bauer-at.com/wp-content/uploads/IMG_E55721-768x432.jpg)

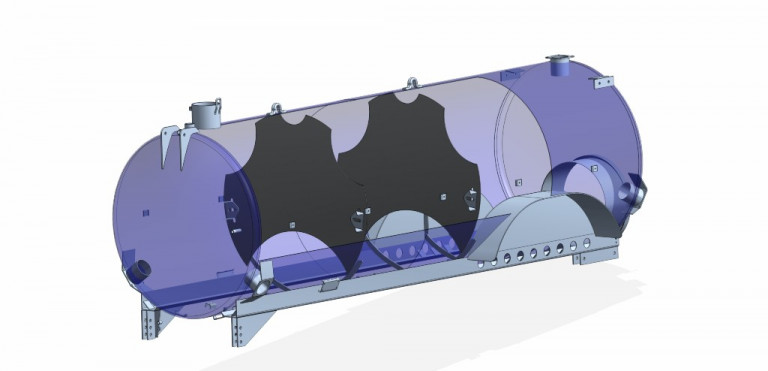

Our experienced construction engineers develop new components and equipment focusing on well proven technology. BAUER slurry tankers are drawn in full 3D on CAD design workstations, ensuring that spare parts are available even after many years. Test runs and load tests make sure that every prototype is ready for series production.

Your confidence is based on our experience.

In a special process, the single parts of the tanker (rings of steel) are beaded and later put together with hydraulic presses to obtain a perfectly round shape. Later on, the joints are automatically welded which ensures an optically perfect weld seam of high quality. The standard hot-dip galvanization according to DIN EN ISO 1461 ensures long-term corrosion protection. The high-gloss galvanization with the typical "zinc flower" gives our tankers an amazing appearance. In order to preserve the appearance over many years, all galvanized tankers are finished with a special passivation.

Wheel recesses or wheel boxes reduce the volume. Not at BAUER! Due to the in-house production of our tankers, the length of tanker is again enlarged approximately to the nominal volume. The advantages of a recess in the tanker are:

Depending on the tanker type, the tractor and application, the types of drawbars offer different advantages. Therefore, we are offering the complete range:

An optional drawbar adjustment is available for all drawbars to adjust the tanker inclination or hitch height of different tractors. An additional extension as a drawbar suspension via nitrogen accumulators is available.

Big volume tankers require more road safety which is ensured by one or more anti-surge baffles, depending on the tanker size. Anti-surge baffles are a standard in all models from size 55 up.

The insensitivity to foreign matters in the slurry is one of the strengths of the vacuum tanker. However, this requires good accessibility to the tank. For this reason, we manufacture a tanker lid which can be opened completely up to a tanker diameter of Ø1250mm and a recessed manhole from a tanker diameter of Ø1400mm. The manhole with Ø750mm combines the advantages of good accessibility and low effort with only a few screws to open. Easy maintenance.

Bauer vacuum tankers are provided with a double overpressure protection in standard execution. A sealed pressure relief valve with blow-off hose regulates the pressure and the spring-loaded dome lid provides double pressure protection in the tank.

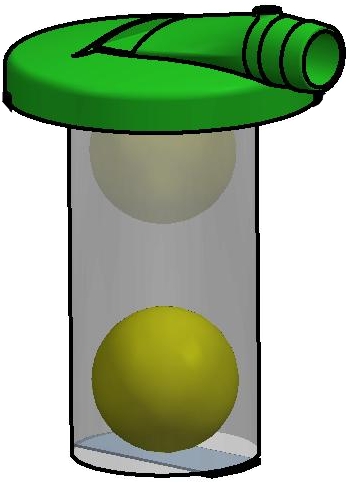

Ball valves in the dome and in the siphon provide double safety against slurry entering the compressor. The under- and overpressure can be read from the glycerine manovacuumeter.

With the optional preparation for hose applicator, Bauer vacuum tankers can be equipped for hose applicators or trailing shoe applicators. The possible parameters are already taken into consideration in the design and the tanker is equipped accordingly.

An additional dome on top of the tanker is available in 2 executions. As a manually opened lid with a diameter of 320mm or as a hydraulic version with a diameter of 450mm.

The flow-optimised cast pump housing, adopted from BAUER pumping technology in which an impeller insensitive to foreign bodies runs at high speed, considerably supports the normal suction process. The compressor can be run at low speed. This makes the vacuum tanker almost completely full again and reduces the filling time.

The slurry is agitated in this area by air flowing in via sleeves. Check valves protect the compressor. Tankers with a compressor size of B33 to B83 are equipped with one mixing tube. As from compressor type Star, two mixing tubes are installed.

When driving downhill, a vacuum tanker cannot be emptied completely for reasons of the system. The downhill spreader allows to select the spreading situation and to empty the tanker completely.

And without getting off the tractor. With a suction arm (automatic suction), you hydraulically dock the suction line into a suction funnel placed on the slurry pit/lagoon. You start/stop the filling process directly from the tractor via hydraulically controlled suction slides. Different types of suction arms are available.

The system based on two tank chambers automatically empties the rear chamber first whereby the first one always receives the full vertical load. This allows for better traction on the tractor wheel and for safe driving off-road. Available as from type V77.

This allows a subsequent attachment of a spreading boom at any time. In this case, the tanker is equipped with a flat manhole so that the spreading device can be attached as closely as possible to the tanker body. Furthermore, an additional outlet flange for the feed line of the spreading boom is placed at the top rear of the tanker.

Our vacuum tankers are also available in tandem execution.

Vacuum tandem tankers from 10,000 litres have been equipped with the proven 4-spring tandem group for many years now. Sturdy suspended parabolic springs combined with the compensating rocker and, on large series, with additional longitudinal stabilisers provide driving safety and high load-bearing capacity. From size V100TL, a self-steering on the second axle is included as standard. This ensures low tyre wear and soil protection in the field.

Type series V63T to V81TL are equipped with spring-loaded bogie axle groups.

In tandem vacuum tankers from 12m³, the first-class Star compressors used are optimally matched to the tanker volumes and ensure the maximum technical vacuum for effective suction.

Find out everything about our new innovative systems for pivot systems from BAUER.