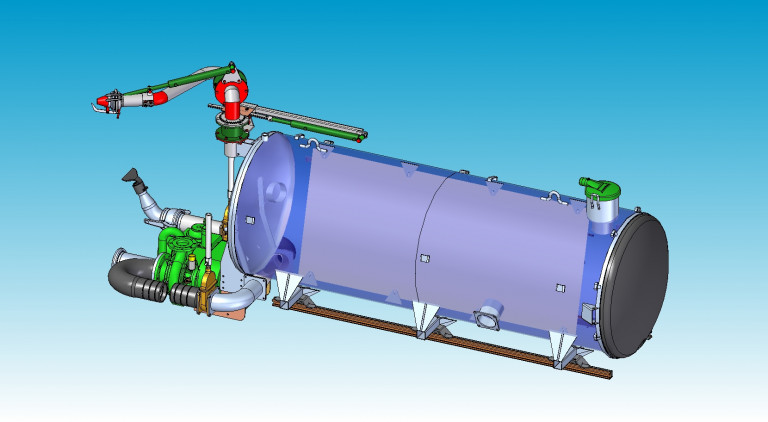

Pick-up tankers are available as vacuum or combi pick-up tankers. The vacuum pick-up tanker has got the properties of a normal vacuum tanker. The combi pick-up tanker comprises the advantages of a high-pressure combi tanker. The combi tanker is available as pick-up of 2,100l to 4,000l for the common transporters. Matched brackets offer secure adaptation to the transporters. Matched tank diameters, any PTO drives and mounting sets necessary are available for the different transporter wheelbases.

![KOMPRESSOR frei[1]](https://www.bauer-at.com/wp-content/uploads/KOMPRESSOR-frei1-768x620.jpg)

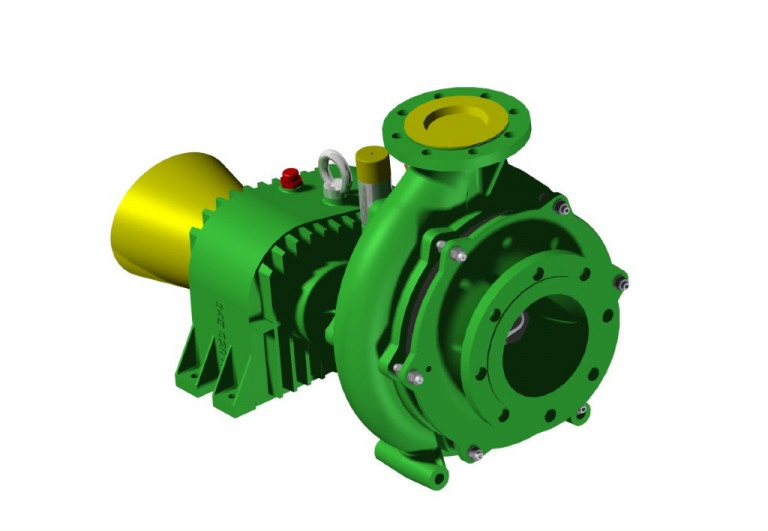

For decades, the BAUER compressor has been synonymous with reliability and durability. High-quality lamellar graphite cast and the very precise machining on CNC-controlled machining centres enable a high degree of efficiency, which is reflected in the world-famous suction and pressure characteristics. Every compressor has to prove its high performance requirements for vacuum and pressure on the factory's own test bench - only then is it delivered to you.

Original BAUER Combi Unit - Made in AUSTRIA

![IMG_E5572[1]](https://www.bauer-at.com/wp-content/uploads/IMG_E55721-768x432.jpg)

Our experienced construction engineers develop new components and equipment focusing on well proven technology. BAUER slurry tankers are drawn in full 3D on CAD design workstations, ensuring that spare parts are available even after many years. Test runs and load tests make sure that every prototype is ready for series production.

Your confidence is based on our experience.

The serial-hydraulically operated slurry gun provides an optimal swivelling range in horizontal and vertical direction. Horizontal swivelling is carried out through a sturdy rack-and-pinion technique. The nozzle can be cleaned easily via an HK coupling. The central arrangement allows a distribution angle close to the tanker on both sides.

In a special process, the single parts of the tanker (rings of steel) are beaded and later put together with hydraulic presses to obtain a perfectly round shape. Later on, the joints are automatically welded which ensures an optically perfect weld seam of high quality. The standard hot-dip galvanization according to DIN EN ISO 1461 ensures long-term corrosion protection. The high-gloss galvanization with the typical "zinc flower" gives our tankers an amazing appearance. In order to preserve the appearance over many years, all galvanized tankers are finished with a special passivation.

The pick-up tankers are equipped with a hot dip galvanised longitudinal partition wall as standard. This provides safety and guarantees good driving behaviour of the transporter on steep mountain meadows.

Bauer vacuum tankers are provided with a double overpressure protection in standard execution. A sealed pressure relief valve with blow-off hose regulates the pressure. The spring-loaded dome lid provides double pressure protection in the tank.

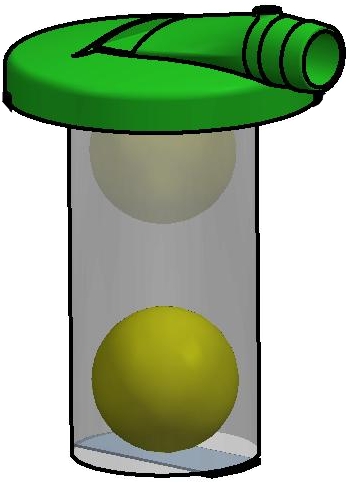

Ball valves in the dome and in the siphon provide double safety against slurry entering the compressor. The under- and overpressure can be read from the glycerine manovacuumeter.

When driving downhill, a combi tanker cannot be emptied completely with the baffle plate for reasons of the system. By driving downhill, the spreading situation can be selected and the tanker can be emptied completely. This option is not required for the slurry gun function.

The corresponding mounting sets and any PTO drives necessary are available for the different transporters.

Find out everything about our new innovative systems for pivot systems from BAUER.