French company Listech has been a dealer of Bauer slurry technology and manufacturer of umbilical systems for many years. Listech showed Growing News how the Bauer Lagoon Mixer is used in a biogas plant.

In Villers-Les-Ormes, a 460-strong community in the department Indre in central France, we meet Fréderic Lagenette, who, as operations manager of the Ceres machine community (French: CUMA), manages an area of around 3,000 hectares. Furthermore he is also responsible for digestate management of the company Méthavert who operates a biogas plant producing 15,000 cubic meters of digestate per year.

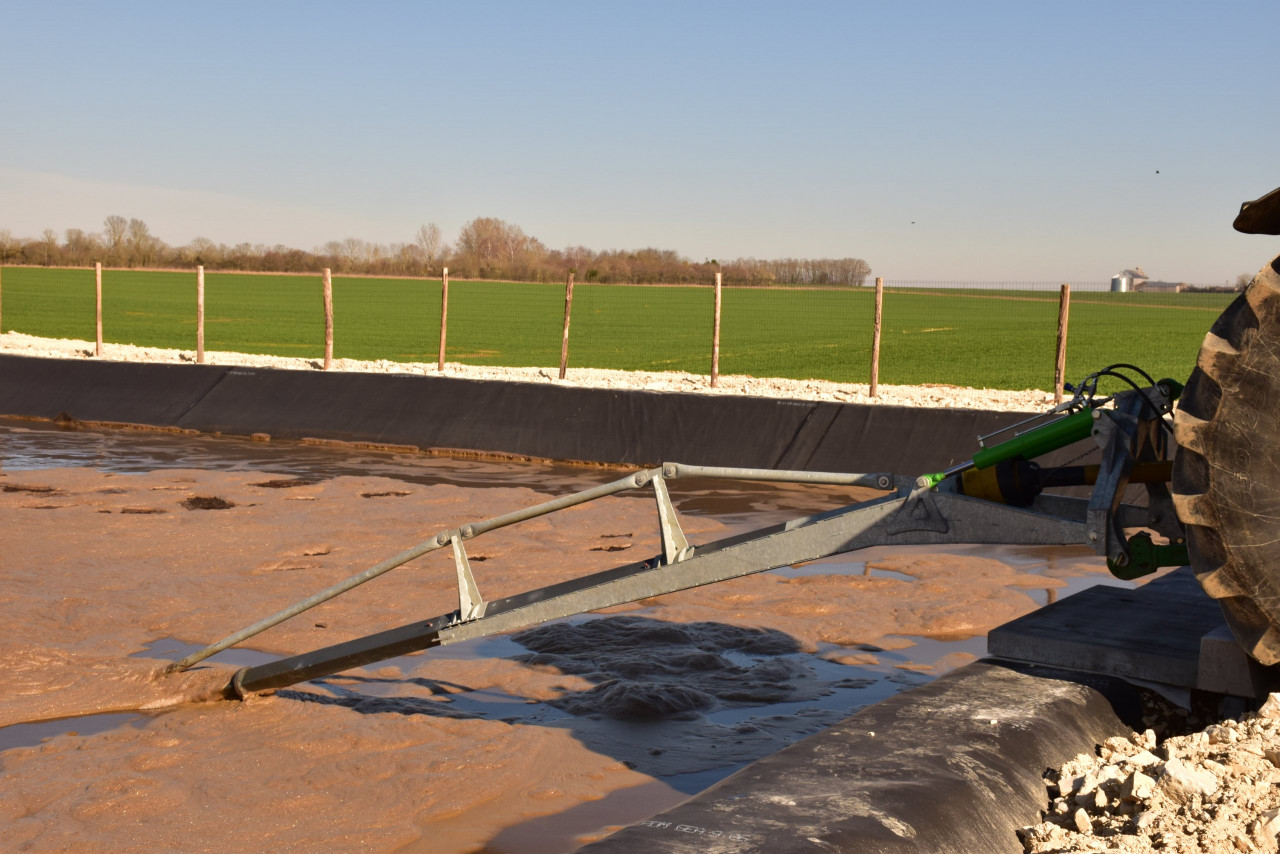

We follow the operations manager to one of the lagoons where the digestate is stored to see their Bauer MTXH-L mixer in action, bought on the advice of Bauer dealer Listech. The mixer plays an important role in spreading the digestate. Because only if the medium is prepared accordingly and the surface crust and the liquid form a homogeneous mass the digestate can be spread onto the fields with the umbilical system without any problems.

Driven by a tractor, the seven meter long mixer is put into operation and slowly lowered into the 5,000 cubic meter lagoon. In combination with the tractor’s lifting mechanism and a hydraulic upper linkage, the optimal position of the agitator rod in the lagoon can be easily adjusted from the driver's seat. First, the digestate is mixed on the surface for a few hours. After that, the mixer is lowered to stir the liquid at the bottom of the lagoon. The Bauer MTXH-L mixer can be used at a speed of up to 1,000 rpm (in this case however, Listech recommends 600 to 700 rpm).

To ensure that the entire lagoon is mixed, the mixer is used at different points. "It is important to start the mixer 24 hours before the start of spreading and to keep it running during this time so that the digestate is optimally mixed and can be easily spread onto the fields with the umbilical system," says Lagenette. After use, the mixer only needs to be washed and greased.

Designed for an output power of up to 250 HP (180 KW) at 1,000 revolutions per minute at the PTO shaft, the mixer produces a homogenized, easy-to-spread natural fertilizer. The mixer consists of: lifting frame, agitator rod, agitator head with agitator blades and protective bar as well as a stable framework.

Benefits:

Find out everything about our new innovative systems for pivot systems from BAUER.